A Course in Woodturning

by Milton and Wohlers; 1919

|

2. CALIPERING FOR DIAMETER. The true diameter is then calipered the same as in spindle work. 3. SMOOTHING CUT. A smoothing cut is taken with a skew chisel the same as in spindle work. |

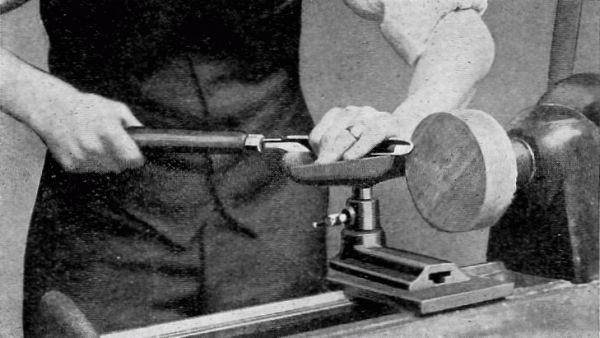

Fig. 15.

4. ROUGHING CUT ON THE FACE. (¾" GOUGE.) FIG. 15. The rest is now placed parallel to the bed of the lathe and slightly above the center of the spindle. Place the gouge on the rest on its edge with the grind toward the stock and parallel to the face to be surfaced. The nose of the gouge is the cutting point.

The handle is then raised and the cutting point is forced toward the center. A very thin shaving should be taken. If the gouge is allowed to roll back so the grind above the cutting point comes in contact with the wood it is sure to catch and gash the wood.